Oil Test Kit / Patch Test Kit

60000 INR/Number

தயாரிப்பு விவரங்கள்:

- மாதிரி அளவு Up to 5 ml oil per test

- மேக்ஸ் உயரம் 115 mm

- அம்சங்கள் Portable, easy manual operation, no power required

- பெருகிவரும் வகை Bench or portable

- டெஸ்ட் ரேஞ்ச் Visual detection for Solid Contaminant in Oil

- ஆட்டோமேஷன் தரம் Manual

- அளவிடும் வீச்சு Qualitative (Visual Patch Test)

- மேலும் பார்க்க கிளிக் செய்யவும்

X

விலை மற்றும் அளவு

- 2

தயாரிப்பு விவரக்குறிப்புகள்

- Manual

- Visual detection for Solid Contaminant in Oil

- 2.2 Kg

- Qualitative (Visual Patch Test)

- 115 mm

- 50 mm

- Up to 5 ml oil per test

- Bench or portable

- Portable, easy manual operation, no power required

- N.A. (Visual comparison)

- Testing solid contaminant levels in lubricating oil & hydraulic oil

- 5°C to 45°C

- N.A.

- Single test

- Manual

- Immediate (within minutes)

- Field or laboratory patch test analysis

- 1

- 1/4 BSP

- Ambient

- No Electronic Display

- 47 mm

- 30-80% RH

- Subjective, based on visual inspection

- Manual

- N.A.

- Manual

வர்த்தகத் தகவல்கள்

- வாரம்

தயாரிப்பு விளக்கம்

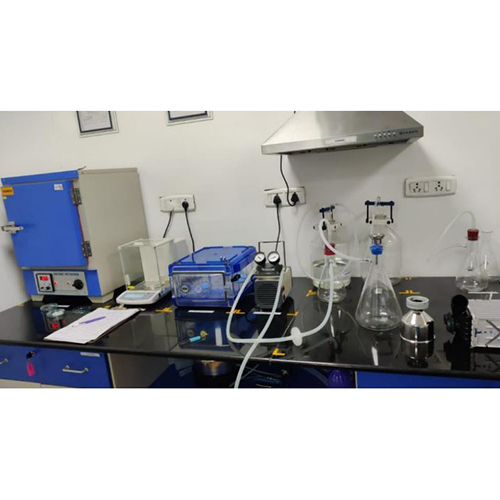

OIL TESTING KIT OIL PATCH TESTING

Oil Testing Kit-(Oil patch Testing) is an onsite tool to determine quality and changes in oil conditions.

Oil Patch Testing Kit is an oil analysis equipment. Now a days, oil analysis is not just important for the oil and lubricant industry, but also used in other industries like automotive, aerospace, energy supply etc. Previous studies shows that nearly 80% of all machine failures are related to oil contamination.

This is like an engineers stethoscope that checks the pulse of the machine by visually analyzing the condition of machine oil.

- Conical flask, Funnel

- Metallic Clamp

- 100 X Microscope (Optional)

- 0.8 micron membrane filter paper(1 Box 100Nos.)

- 500 ml plastic Benzene bottle

- Vacuum pump with flexible pipe

- Sintered glass membrane holder

Field and Laboratory Applications

Designed for both field and laboratory environments, this oil patch test kit allows users to quickly assess lubricant or hydraulic oil contamination levels anywhere needed. Its manual control and lightweight build ensure it's easy to transport and operate in demanding industrial, automotive, or maintenance settings.

Easy Visual Contaminant Detection

By passing an oil sample through a filter patch and comparing the result to a standard chart, users can visually evaluate the presence of solid contaminants accurately. There's no need for electronic displays or complex power requirements, making every test straightforward and efficient.

Comprehensive Kit Contents

Included in the kit are all essential tools: filter paper patches (47 mm), suction bottle, glass syringe, patch holder, clamp, reservoir bottle, and a clear instruction manual. This complete package streamlines the testing process, ensuring that professionals can start analysis immediately upon receipt.

FAQ's of Oil Test Kit / Patch Test Kit:

Q: How do I use the Oil Test Kit (Patch Test Kit)?

A: To conduct a patch test, draw up to 5 ml of oil using the glass syringe, pass it through the 47 mm filter paper using the manual suction bottle, then compare the resulting patch to a standard chart. Detailed steps are provided in the included instruction manual.Q: What types of oil can be tested with this kit?

A: This kit is suitable for lubricating and hydraulic oils, making it ideal for use in industrial, automotive, and machinery maintenance applications.Q: When should I perform an oil patch test?

A: Carry out the test as part of routine maintenance checks or whenever you suspect contamination in your oil. Regular testing helps prolong equipment life and prevents costly breakdowns.Q: Where can this kit be used?

A: The kit's portable, handheld design is suitable for both field and laboratory environments. It can be mounted on a bench or used directly on-site, wherever oil analysis is required.Q: What are the benefits of using a visual patch test kit for oil analysis?

A: This kit provides immediate visual feedback, requires no power, and supports qualitative detection of solid contaminants. Its simplicity and portability help users monitor and maintain oil quality efficiently.Q: What is the cleaning and maintenance process for this kit?

A: Maintenance is simple: clean the non-disposable components with suitable solvents after use, and replace filter paper patches for each test. The ease of cleaning ensures consistent, reliable results.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email